With straitened economic times and the ever-increasing cost of drug production, pharmaceutical companies everywhere are constantly on the lookout for new technologies which will help them streamline their manufacturing processes and make them cheaper and more efficient. Now more advanced vacuum technology might be one solution to the problem, enabling drugs manufacturers to speed up the production of tablets, improve working conditions and boost company productivity altogether.

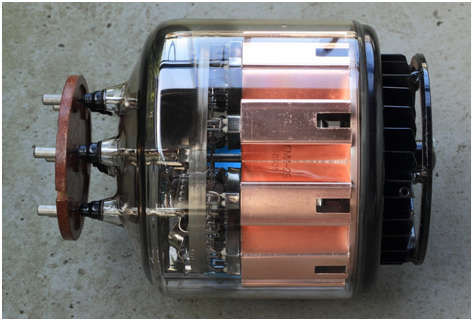

Advanced vacuum technology

As more than 75% of all pharmaceutical produce sold is in the form of solid tablets, ensuring they are manufactured as safely and speedily as possible is critical if a drug manufacturer is to stay ahead of its rivals and meet consumer demand. A vacuum conveyor greatly reduces the time spent on production by automating the conveying process, thus improving productivity and cutting costs.

A vacuum conveyor can also see companies enjoy reduced energy consumption. With decentralised vacuum systems being made ever more efficient, multistage ejector technologies mean a vacuum can be applied where it’s needed and no additional energy is necessary to compensate for distance. Low maintenance systems are also easier to clean, bringing the added benefit of decreased downtime when processing machinery needs to be cleaned to avoid cross-contamination.

With countless batches of tablets rolling off the production line every day, vacuum technology can help avoid tablet breakages and prevent segregation or particle separation before tablets are compressed.

Improved working environments

According to Pharmaceutical Online, more and more companies are adopting vacuum technology in a bid to cut manufacturing costs and improve the quality of the products they offer.

Vacuum technology also has a major role to play in improving the working environment for staff, reducing noise, heat and dust to ensure the workplace is healthier and there is less risk of contamination. With fewer moving parts, advanced vacuums such as those sold by http://www.aptech.uk.com/pneumatic-conveying/vacuum-conveying/ can significantly cut the risk of employees being injured at work.

Such vacuum systems are now easier to assemble and take apart, meaning more uptime as lines have to be stopped less often for workers to clean components or adjust equipment between batches. It seems likely that as such vacuum conveyors become faster, easier to operate and more efficient, greater numbers of pharmaceutical manufacturers will invest in them as a means of cleaning up and speeding up their processes.